20%-30% FASTER CUTTING SPEED WITH HIGHER QUALITY CUTTING EDGE THAN FIBER LASERS

VERSATILITY

Lasertech lasers handle the entire laser cutting industry: Mild Steel (70%), and Stainless Steel (20%)

CAPABILITY

Lasertech Molecular lasers of Series AL cut Mild Steel faster than Fiber lasers, and produces the highest quality edge on stainless steel

EFFICIENCY

AL lasers cut Mild Steel 30-40% faster than a Fiber laser can, and as a result cuts operating costs and the production time

Multiple Beam Modes – TEM 00 or “A” Mode

The ability to change the Polarization of the beam

The ability to adjust the size of the focusing spot and/or modify the power density

Lasertech’s AL lasers are 6% more optically efficient than other CO2 lasers.

Increasing the cutting speed of AL lasers means a reduction in operational electrical consumption, which directly affects production costs.

AL lasers provide the cutting speed and quality needed for various materials that a Fiber Laser could not achieve such as polymer, glass, ceramic, plastic, wood, etc.

The above claims have been tested and proven to be true against our competitors by analysis of calculations in a testing environment.

FACT:

Fiber laser use 2000 watts with a cutting speed of 70 in/min, for 6 mm mild steel.

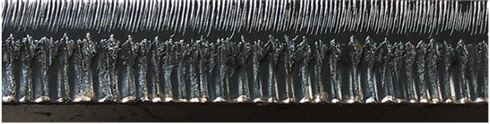

This picture shows the typical cutting quality by Fiber laser at 70 in/min.

Fiber laser 2000 watts cutting speed 40 in/min, mild steel 6 mm.

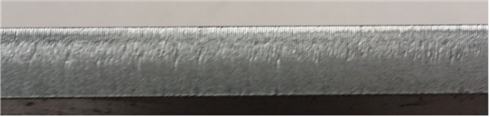

The picture below shows the reduced speed of cutting by Fiber laser

An 80% speed reduction with the fiber laser passes the standard requirements for the quality edge.

Quality cutting edge for Stainless Steel 8mm